wide variety

product & services

technologies / equipment

A full range of services needed while PCBs and PCBAs manufacturing for the complete implementation of your technological solutions.

1. Full range of EMS services

2. Printed circuit boards of any level of complexity

- DFM analysis

- PCB data processing for pre-production engineering

- PCB design and redesign

- PCBs of up to 40 layers

- RF / Microwave PCBs

- Impedance control

- PCB manufacturing using lead-free and mixed technologies

- Prototype PCB production

- Mass production of PCBs of any complexity

- Cleaning

- Laser marking of PCBs

- Conformal coating

3. PCB assembly

- Surface mounting stencil design

- PCB SMT and THT assembly

- PCB PoP and BGA, PGA, LGA etc. assembly

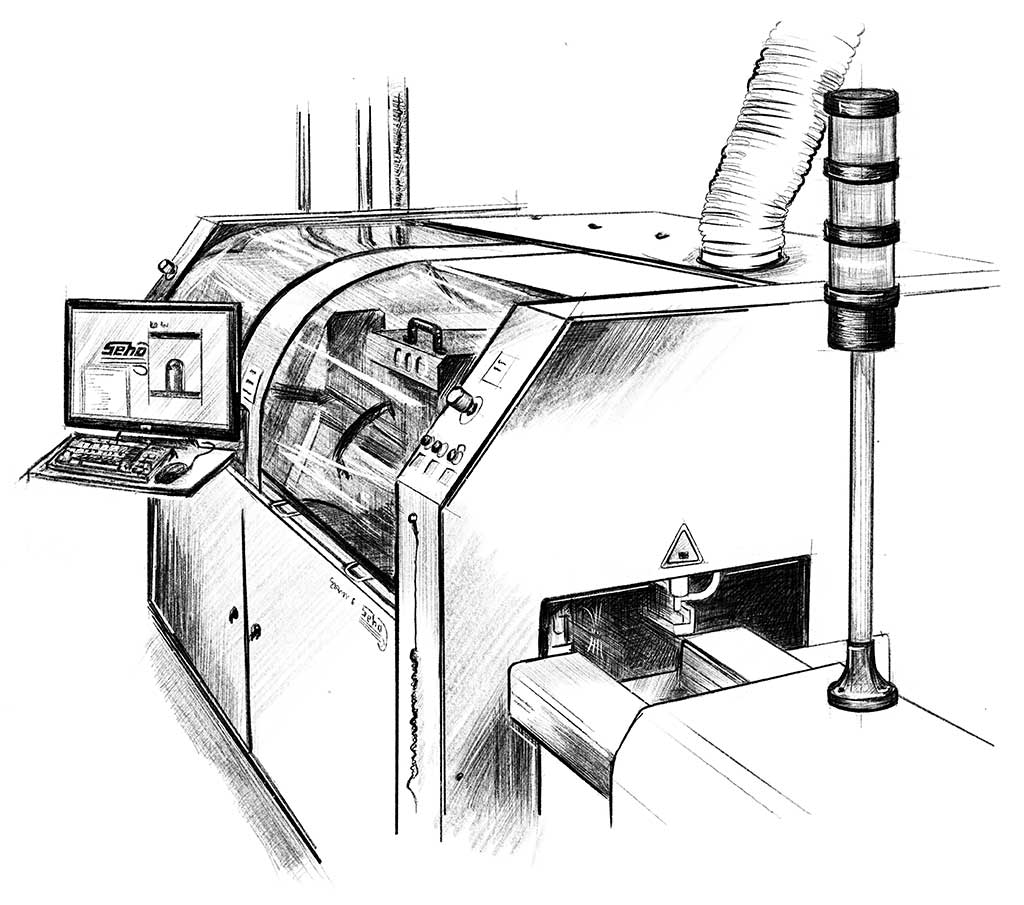

- Reflow soldering in convection and vapor-phase ovens, selective soldering, hand mounting

- PCB assembly using both non-lead-free lead-free technologies

- Assembly of components from size 01005 to 200x110mm

- BGA, µBGA, Flip Chip, CSP, TQFP and Fine pitch package assembly and reworking

- BGA laser reballing

- Mass production of SHF PCBAs

- PCBA cleaning

- PCBA conformal coating. Selective automatic conformal coating

- All types of PCBA testing, inspection and control

- visual and automated optical inspection

- stencil printing process control

- X-ray inspection

- in-circuit testing (ICT)

- functional control and boundary scan JTAG

- Design and manufacture of stands for functional control

- Press-Fit Technology

- PCBA testing

- Box build

- Traceability at all stages of production

4. Multi-stage quality control system

- DFM analysis

- PCB electrical control

- Impedance control

- PCB incoming inspection before assembly

- Electronic component incoming inspection

- Stencil printing process control using SPI-AOI systems

- Visual inspection

- AOI

- X-Ray & 3DX-Ray Inspection

- ICT

- JTAG Boundary scan

- cleaning quality control

- Functional control

5. Product testing

- Climatic testing

- Vibration testing

- Vacuum testing

- Other kinds of testing

![[Translate to English:] Печатные платы любого уровня сложности](/fileadmin/_processed_/5/6/csm_16_02_406e0ddc36.jpg)

![[Translate to English:] Контрактное производство электроники](/fileadmin/_processed_/1/c/csm_18_06e48df062.jpg)